-

-

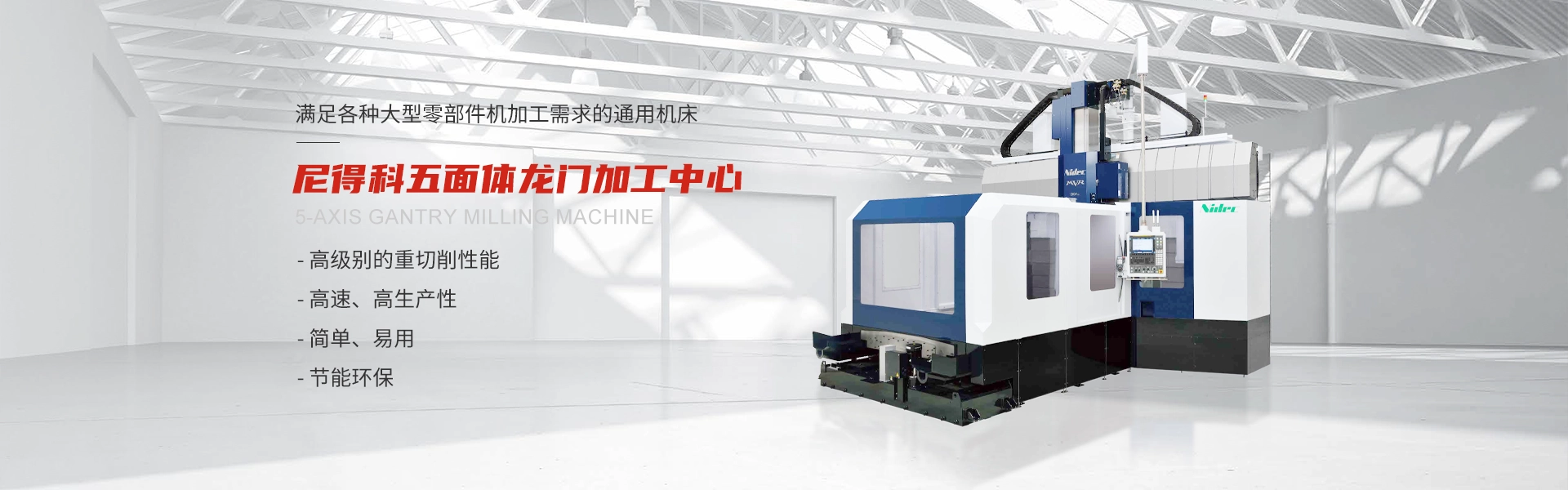

五轴龙门 MVR Ax系列

● 满足各种大型零部件机加工需求的通用机床,切削性能好、快速、操作简单,提高了客户的生产效率高。

● 其工作台尺寸能应对大型工件加工,具有丰富的主轴附件,还有包含自动托盘更换装置在内的自动化系统等多种选择,可以满足客户多种多样的用途需求。-

0.000.00

-

商品描述

● 满足各种大型零部件机加工需求的通用机床,切削性能好、快速、操作简单,提高了客户的生产效率高。

● 其工作台尺寸能应对大型工件加工,具有丰富的主轴附件,还有包含自动托盘更换装置在内的自动化系统等多种选择,可以满足客户多种多样的用途需求。

实现了高级别的重切削性能

立轴、卧轴在相同条件下,可进行强力的重切削

高速・高生产性

卓越的机床刚性和优异的衰减性

简单、易用 ~高效进行单一品种、小批量加工~

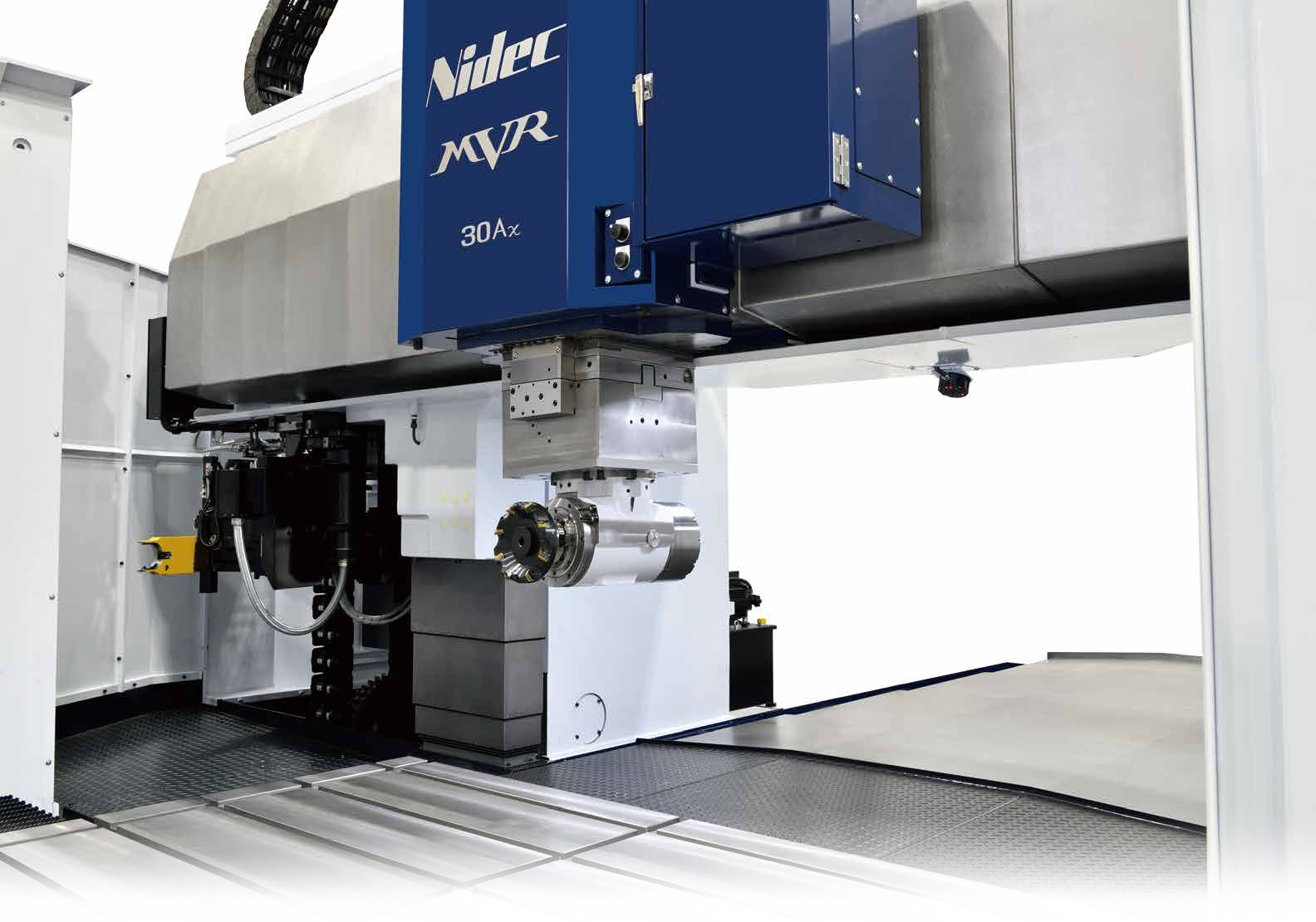

MVR25Ax

MVR25Ax

柱间喉部间隙

2,050

主轴端到工作台面的距离

标准:1,650

可选:2,010

MVR30Ax

柱间喉部间隙

2,550

主轴端到工作台面的距离

标准:1,650

可选:2,010

MVR35Ax

柱间喉部间隙

3,250

主轴端到工作台面的距离

标准:1,850

可选:2,150

MVR40Ax

柱间喉部间隙

3,750

主轴端到工作台面的距离

标准:1,850

可选:2,150

MVR45Ax

柱间喉部间隙

4,250

主轴端到工作台面的距离

标准:2,150

| 項目 | MVR25Ax | MVR30Ax | MVR35Ax | MVR40Ax | MVR45Ax | |||||||

| 立柱门宽的距高mm | 2,050 | 2,550 | 3,250 | 3,750 | 4,250 | |||||||

| 工件安裝面到主轴端面的距离 | std. mm | 1,650 | 1,650 | 1,850 | 1,850 | 2,150 | ||||||

| opt. mm | 2,010 | 2,010 | 2,150 | 2,150 | - | |||||||

| 工作台 | 作业面尺寸 | 宽度 | mm | 1,500 | 2,000 | 2,500 | 3,000 | 3,500 | ||||

| 长度 | 横槽规格 | std. mm | 3,000 | 3,000 | 4,000 | 4,000 | 6,000 | |||||

| opt. mm | 4,000 | 4,000 | - | - | - | |||||||

| 5,000 | 5,000 | 5,000 | 5,000 | - | ||||||||

| 6,000 | 6,000 | 6,000 | 6,000 | - | ||||||||

| 8,000 | 8,000 | 8,000 | 8,000 | 8,000 | ||||||||

| - | 10,000 | 10,000 | 10,000 | 10,000 | ||||||||

| 纵槽规格 | opt. mm | 2,700 | 2,700 | - | - | - | ||||||

| 3,700 | 3,700 | 3,700 | 3,700 | - | ||||||||

| 4,700 | 4,700 | 4,700 | A700 | - | ||||||||

| 5,700 | 5,700 | 5,700 | 5,700 | - | ||||||||

| 7,700 | 7,700 | 7,700 | 7,700 | - | ||||||||

| 承重/工作台长度 | 横槽规格 | std. kg/mm | 12,000 / 3,000 | 20,000 / 3,000 | 25,000 / 4,000 | 25,000 / 4,000 | 35,000 / 6,000 | |||||

| opt. kg/mm | 15,000 / 4,000 | 25,000 / 4,000 | - | - | - | |||||||

| 18,000 / 5,000 | 30,000 / 5,000 | 30,000 / 5,000 | 30,000 / 5,000 | - | ||||||||

| 20,000 / 6,000 | 30,000 / 6,000 | 30,000 / 6,000 | 30,000 / 6,000 | - | ||||||||

| 20,000 / 8,000 | 30,000 / 8,000 | 30,000 / 8,000 | 30,000 / 8,000 | 30,000 / 8,000 | ||||||||

| 30,000 / 10,000 | 30,000/10,000 | 30,000 / 10,000 | 25,000 / 10,000 | |||||||||

| 纵槽规格 | opt. kg/mm | 12,000 / 2,700 | 20,000 / 2,700 | - | - | - | ||||||

| 15,000 / 3,700 | 25,000 / 3,700 | 25,000 / 3,700 | 25,000 / 3,700 | - | ||||||||

| 18,000 / 4,700 | 30,000 / 4,700 | 30,000 / 4,700 | 30,000 / 4,700 | - | ||||||||

| 20,000 / 5,700 | 30,000 / 5,700 | 30,000 / 5,700 | 30,000 / 5,700 | - | ||||||||

| 20,000 / 7,700 | 30,000 / 7,700 | 30,000 / 7,700 | 30,000 / 7,700 | - | ||||||||

| 各轴移幼量 | 工作台前后(x轴) | std. mm | 3,200 | 3,200 | 4,200 | 4,200 | 6,200 | |||||

| opt. mm | 4,200 | 4,200 | - | - | - | |||||||

| 5,200 | 5,200 | 5,200 | 5,200 | - | ||||||||

| 6,200 | 6,200 | 6,200 | 6,200 | - | ||||||||

| 8,200 | 8,200 | 8,200 | 8,200 | 8,200 | ||||||||

| 10,200 | 10,200 | 10,200 | 10,200 | |||||||||

| 滑枕鞍座左右(y轴) | std. mm | 2,500 | 3,000 | 3,500 | 4,000 | 4,500 | ||||||

| opt. mm | 2,650 | 3,150 | 3,900 | 4,400 | 4,900 | |||||||

| 滑枕上下((Z轴) | std. mm | 800 | ||||||||||

| 橫梁上下(w轴 | mm | 1,000(工件安装面到主轴端面的距离为1,650mm时) 1,100(工件安装面到主轴端面的距离为2,010mm时) | 1,300 | |||||||||

| 主轴头 | 滑枕尺寸mm | 350 | ||||||||||

| 主轴端的锥孔 | JIS B6101 50号(大昭和精机 BIG-PLUS) | |||||||||||

| 主轴直径mm | φ110 | |||||||||||

| 主轴转速 | std. mind | 20~6,000(22/30kW:低速/高速) | ||||||||||

| opt. min'l | 40~10,000(18,5/26kW 22/30kW:连续/30分钟) | |||||||||||

| 11~4,000(22/30kW:连续/30分钟) | ||||||||||||

| ATC | 刀具收納数量 | 把 | 60(std.)80、100、120、180(opt.) | |||||||||

| 刀具最大直径 | mm | φ260 | ||||||||||

| 刀具最大很度 | mm | 500 (std)600 (opt) | ||||||||||

| 刀具最大重量 | kg | 25 (std)30 (optj | ||||||||||

| 切削进给速度 | x轴.Y轴.Z轴 | mm/mmn | 1~10,000 | |||||||||

| 快速进给速度 | x轴(3,200mm) | mm/mmn | 30,000 | 30,000 | - | - | - | |||||

| x轴(4,200mm) | mm/mmn | 30,000 | 30,000 | 22,000 | 22,000 | - | ||||||

| x轴(5,200mm) | mm/mmn | 30,000 | 30,000 | 22,000 | 22,000 | - | ||||||

| x轴(6,200mm) | mm/mmn | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | ||||||

| x轴(8,200mm) | mm/mmn | 15,000 | 15,000 | 15,000 | 15,000 | 15,000 | ||||||

| x轴(10,200mm) | mm/mmn | 12,000 | 12,000 | 12,000 | 12,000 | |||||||

| y轴 | mm/mmn | 32,000 | 32,000 | 32,000 | 28,000 | 22,000 | ||||||

| z轴 | mm/mmn | 20,000 | - | - | ||||||||

| w轴 | mm/mmn | 5,000 | - | - | ||||||||

| 机床质量/工作台长度 | std. kg/mm | 35,890 / 3,000 | 39,390 / 3,000 | 59,340 / 4,000 | 67,340 / 4,000 | 104,740 / 6,000 | ||||||

| opt. kg/mm | 39,440 / 4,000 | 42,940 / 4,000 | - | - | ||||||||

| 42,990 / 5,000 | 46,490 / 5,000 | 65,390 / 5,000 | 73,390 / 5,000 | - | ||||||||

| 46,540 / 6,000 | 50,040 / 6,000 | 71,440 / 6,000 | 79,440 / 6,000 | - | ||||||||

| 53,640 / 8,000 | 5 7,140/8,000 | 83,540 / 8,000 | 91,540 / 8,000 | 122,840 / 8,000 | ||||||||

| - | 64,240 / 10,000 | 95,640 / 10,000 | 103,640/10,000 | 140,940/10,000 | ||||||||

适用行业

航空航天领域,能源领域,交通运输业,石油与天然气行业,机器制造领域,模具行业,通用机械板块等

上海君湛机械科技有限公司 版权所有 严禁复制 网站备案号:沪ICP备18037167号-1

公司地址:上海市外高桥自贸区富特东三路526号1幢308、309室 电话:021-50427829 / 50430288